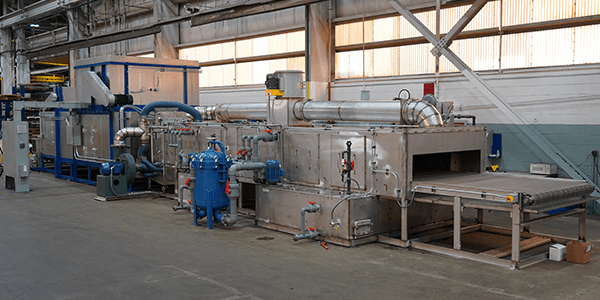

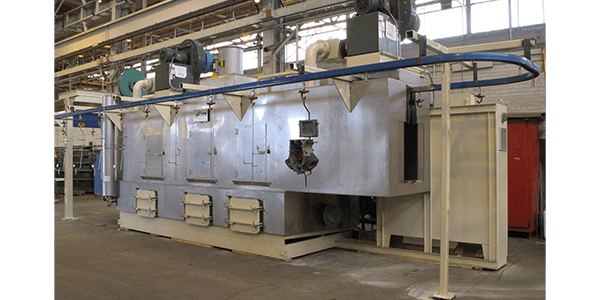

Industrial Parts Washers

Industrial parts washers in a manufacturing facility are a true workhorse in the production line. Parts washers clean oil, chemicals and dirt from parts of all sizes, trays and even pallets. After the parts are washed, they are ready to move through to the next phase of manufacturing, meeting critical part cleaning specifications.

International Thermal Systems manufactures industrial parts cleaners for a wide variety of industries aerospace, automotive, metal stamping, and more. By clearly defining the process objectives and testing parts cleaning in our R&D lab, we select a parts washer that cleans as specified upon installation and will keep manufacturing running smoothly.

In 2013, ITS acquired the Continental Equipment Corporation. We invite all CEC equipment customers to contact us for replacement parts and machine service.