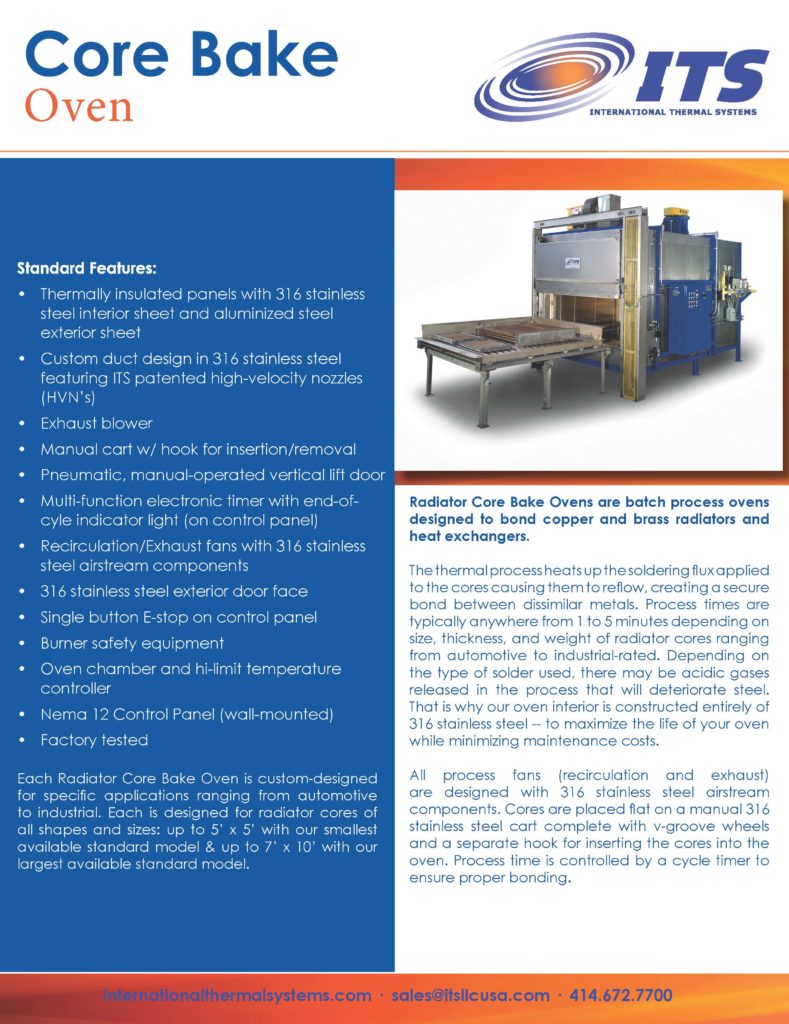

Radiator Core Bake Ovens are batch process ovens designed to bond copper and brass radiators and heat exchangers. The thermal process heats up the soldering flux applied to the cores causing them to reflow, creating a secure bond between dissimilar metals.

Core Bake Oven

Overview

A radiator Core Bake Oven is a batch process oven. Process times are typically anywhere from 1 to 5 minutes depending on size, thickness, and weight of radiator cores ranging from automotive to industrial-rated.

Depending on the type of solder used, there may be acidic gases released in the process that will deteriorate steel. That is why our oven interior is constructed entirely of 316 stainless steel — to maximize the life of your oven while minimizing maintenance costs. All process fans (recirculation and exhaust) are designed with 316 stainless steel airstream components.

Cores are placed flat on a manual 316 stainless steel cart complete with v-groove wheels and a separate hook for inserting the cores into the oven. Process time is controlled by a cycle timer to ensure proper bonding.

Each Radiator Core Bake Oven is custom-designed for specific applications ranging from automotive to industrial. Each is designed for radiator cores of all shapes and sizes: up to 5’ x 5’ with our smallest available standard model & up to 7’ x 10’ with our largest available standard model. Our Standard Core Bake Oven line contains three different size ovens based on industry needs:

- 5’ x 5’ (SCBO.0055)

- 6’ x 7’ (SCBO.0067)

- 7’ x 10’(SCBO.0710)

Features

- Thermally insulated panels with 316 stainless steel interior sheet and aluminized steel exterior sheet

- Custom duct design in 316 stainless steel featuring ITS patented high-velocity nozzles (HVN’s)

- Exhaust blower

- Manual cart w/ hook for insertion/removal

- Pneumatic, manual-operated vertical lift door

- Multi-function electronic timer with end-of-cycle indicator light (on control panel)

- Recirculation/Exhaust fans with 316 stainless steel airstream components

- 316 stainless steel exterior door face

- Single button E-stop on control panel

- Burner safety equipment

- Oven chamber and hi-limit temperature controller

- Nema 12 Control Panel (wall-mounted)

- Factory tested

- Factory direct technical service and spare parts group

Options

- PLC/HMI for process automation

- Drip Pans for flux containment both inside and outside of the oven

- Smoke Capture Hood for vapor escapement through door opening

- Motorized Cart for core insertion

- Automatic Shutdown Circuit for oven purge of flux vapors at shift’s end

- 316 Stainless Steel Oven Exterior (standard for interior)

- UL/CE Listed Electrical Panel – panel inspected, certified, serialized (CE provides declaration of conformity)

- Flux Tank w/ Stand for manual dipping of cores

- Access Plug – removable insulated access panel

- Access Door – oven access is otherwise limited to the product opening for core insertion

Industries

- Aerospace

- Agriculture

- Automotive

- Heavy Duty Equipment

- HVAC

- Mining

- Transportation

Downloads

Read more about the Core Bake Oven

International Thermal Systems Overview

Contact the ITS Oven Group

We are ready to assist with application recommendations and product proposals.