Overview

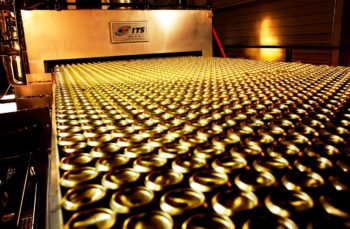

The Can Washer cleans and prepares the interior and exterior surface of the cans.

The multiple stage Can Washers are used in the beverage and food can industries. Can washers can clean several hundred or up to 6,000 cans per minute.

Recover and reuse precious chemical resources with our exclusive patented Belt Vacuum System.

The Can Washer has removable roof panels to access the entire length of the washer interior thus reducing maintenance time and cost.

Our spray risers feature patented quarter-turn quick disconnects and full-length guide rails for easy maintenance and operator safety.