At ITS we are committed to customer satisfaction and developing long term business partnerships with our customers. We created the ITS Research and Development Laboratory to provide testing and validation services for our customer’s processes. We are able to recommend the best process for the specific application BEFORE the machine is engineered and manufactured, which provides the assurance that the ITS washer will be deliver the required cleaning results.

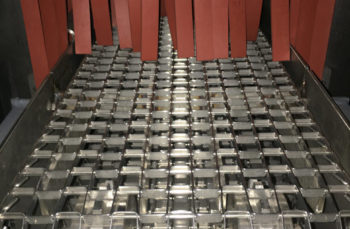

Parts Testing in the ITS Lab

R&D Lab is located at our Milwaukee plant.

Why is Parts Testing Important?

Verifying the correct cleaning process before manufacturing ensures the expected results when machine is built.

We invite our customers to send their dirty parts to ITS and we will test the parts in the lab washer. We return clean parts with a validated cleaning process specific to the application. By testing and validating the cleaning process PRIOR to manufacturing, the customer can be assured that the machine will deliver the expected cleaning results once installed. Testing before manufacturing saves the customer both time and money because the machine is engineered specifically for the customer’s part and process.

Once the testing is complete, the customer will get the tested sample back and a formal test report. The typical test report includes test purpose, test procedure, test result and design recommendation.

“The benefit to the customer is the confirmation of the exact process parameters prior to the engineering and manufacturing of the equipment.”

Dr. Joe Zhao, Ph,D.

Research & Development Manager

Watch the video to learn more about parts testing.

Downloads

Aqueous Washing Systems

TruClean Washer Food Processing Case Study

Contact the ITS Washer Group

We are ready to assist with application recommendations and product proposals.