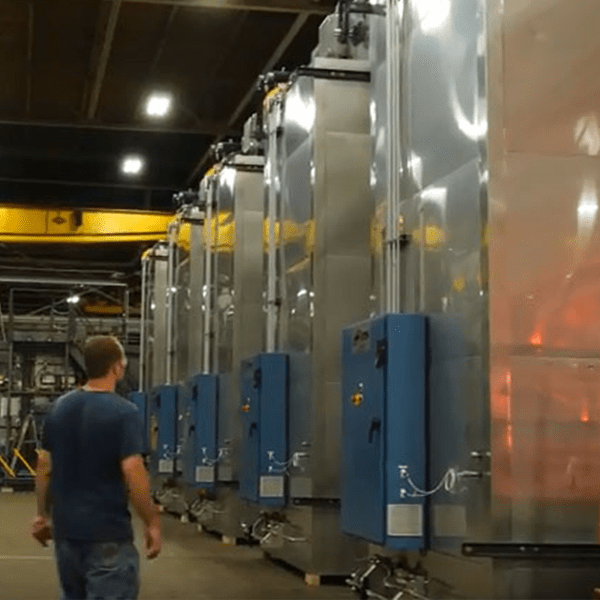

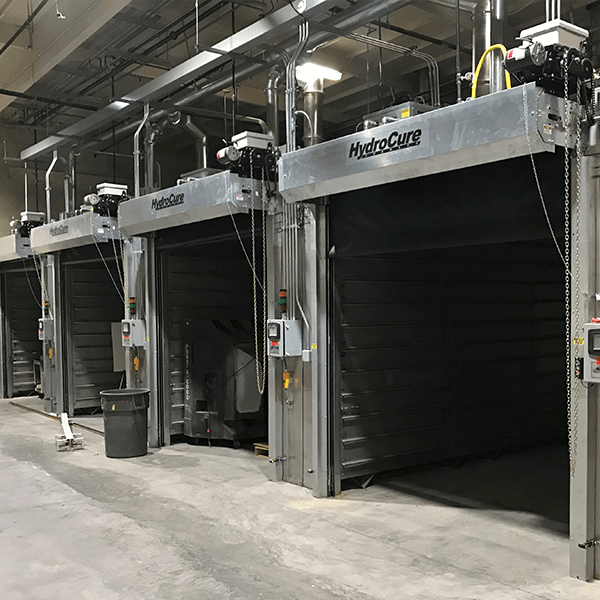

International Thermal Systems HydroCure™ Combination Humidity/Drying Chambers are recognized in the battery industry as the leader in reliability, innovative and intuitive operator friendly design. ITS has installed 1000’s of HydroCure™ Combination Humidity/Drying Chambers throughout the world.

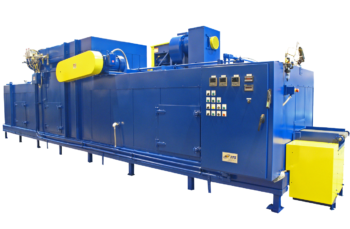

HydroCure Humidity Drying Chamber

HydroCure Humidity Drying Chamber

Watch and learn about the features of the HydroCure drying chamber and why it is the industry leader.

Stack pallets of plates in the sleek, upright design of the HydroCure™ Humidity Drying Chamber.

For the accelerated curing process of lead acid battery plates, you need the HydroCure™ Humidity Drying Chamber.

The purpose of a HydroCure™ Combination Humidity Drying Chamber is to dry and cure the freshly pasted plate grid. Pallets of plates are stacked in the sleek, upright design of the HydroCure™ Humidity Drying Chamber easily. A proprietary High Velocity Nozzle integral design in the supply duct ensures proper crystal growth.

There are many challenges in operating a battery production line efficiently. Proper utilization of the curing chambers’ design and size can be a challenge. If the chamber design is undersized, the production rate will fall short. If the curing chamber is over-sized, excessive curing time cycles will occur. An undersized or over-sized chamber causes a bottleneck in production rates.

Try the NEW Laboratory HydroCure™ Humidity Drying Chamber

Are you looking to fine tune your curing and drying process? Do you need to create a new profile for a new product? Then the Laboratory HydroCure™ is the chamber for you.

The new Laboratory HydroCure™ is available in a 2ft x 2ft x 2ft (610mm x 610mm x 610mm) chamber size. The Laboratory HydroCure™ Humidity Drying Chamber offers all the features of the larger standard chambers. You can be confident your profile will migrate seamlessly to the plant floor.

The Laboratory HydroCure™ is PLC controlled with an easy-to-use operator interface. Use a USB Card to create and load up to twenty custom profiles. Trending in real time appears on the operator interface screen.

Features

- Various models for optimum pallet configuration

- Heavy industrial construction

- Optimum airflow recirculation and exhaust systems

- Durable synthetic door

- Humidity atomizers

- Instruments and controls mounted in a prewired NEMA 12 control panel

- NFPA Compliant

Specifications

- The system incorporates a combination wet wick tray/float tank

- Numerous heat source configurations are available

- The HydroCure™ Humidity Drying Chamber will carry an 12-month extended manufacturer’s warranty from the date of shipment

- We manufacture the HydroCure™ Humidity Drying Chamber worldwide.

- HydroCure™ is Intuitive and Operator Friendly

Industries

- Automotive

- Marine

- Locomotive

- Truck

- Military

- Aerospace

- Golf Cart

- Wheel Chair

Need Service or Parts for your Battery Equipment?

Contact the CSS team for repairs and replacement parts for battery equipment.

Downloads

HydroCure™ Brochure

International Thermal Systems Overview

Contact the ITS Battery Group

We are ready to assist with application recommendations and product proposals.