After the can leaves the washer, dry off ovens are used to dry Aluminum or Steel cans.

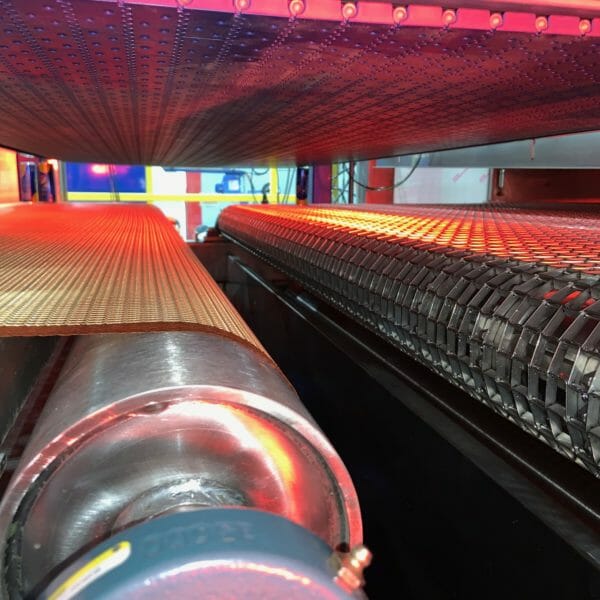

Dry Off Oven

Overview

The Dry Off Oven will completely dry the interior and exterior of the can. ITS engineers specialize in air flow design and customers can be assured that each can will be dry when exiting the oven.

ITS Dry Off Ovens feature proprietary supply and return air technology to thoroughly dry aluminum or steel cans while maintaining complete stability. All supply nozzles are easily removable for ease of maintenance. The Dry-off Oven features access doors along the length of the chamber for complete access to the oven interior.

ITS ovens offer uniform air flow, easy maintenance and production rates of up to 6,000 cans per minute.

The Easy Welding System allows you to easily weld high temperature PTFE coated conveyor belts in less time than previous models. Contact ITS Customer Support Service Group for your Quote on a New EWS Welding Press.

Features

- A Kevlar conveyor belt reduces energy consumption; increases can stability, and eliminate metal fines.

- Automated conveyor belt tracking system.

- Our proprietary supply nozzle design achieves uniform vertical down airflow.

- All supply nozzles are easily removable for greater maintenance access to the oven interior.

- An automatic supply nozzle adjustment system is available to accommodate multiple can heights.

- The Dry-off Oven features access doors along the length of the chamber for complete access to the oven interior.

- Variable Frequency Drives (VFDs).

- The Dry-off Oven contains recirculation and exhaust dampers for uniform airflow balancing.

Specifications

- Heavy gauge Aluminized Steel

- High-density energy-saving insulation

- Panel and can type construction

- Access to the interior of the oven, fan, and burner chamber

- Integrated exhaust with optional air-to-air heat exchanger

Temperature Ranges Up to 500°F (260°C) based on application

Power Source Options

- Main Power Supplies 208 to 690 Volt AC, 50 and 60 HZ

- Control Voltage 24 Volt DC or 120/220 Volt AC

Heat Sources

- LPG

- Natural Gas

- Fuel Oil

- Other Fuel Mixtures

Options

- Single or Multiple Zone Configurations

- Multiple Conveyor Belt Widths (up to 8 feet)

- Ambient Air Coolers

- Designed to meet customer requirements up to 6,000 Cans Per Minute (CPM)

- Vacuum Transfer System

Material Handling Options

- Automatic Conveyor Belt Steering

- Horizontal Conveyor Belts in Synthetic or Stainless Steel

- Perforated or Herringbone Slide Bed Supports

Industries

- Aerosol

- Food

- Beverage

- Pet Food

Downloads

International Thermal Systems Overview

International Thermal Systems Overview

Contact the ITS Metal Packaging Group

We are ready to assist with application recommendations and product proposals.