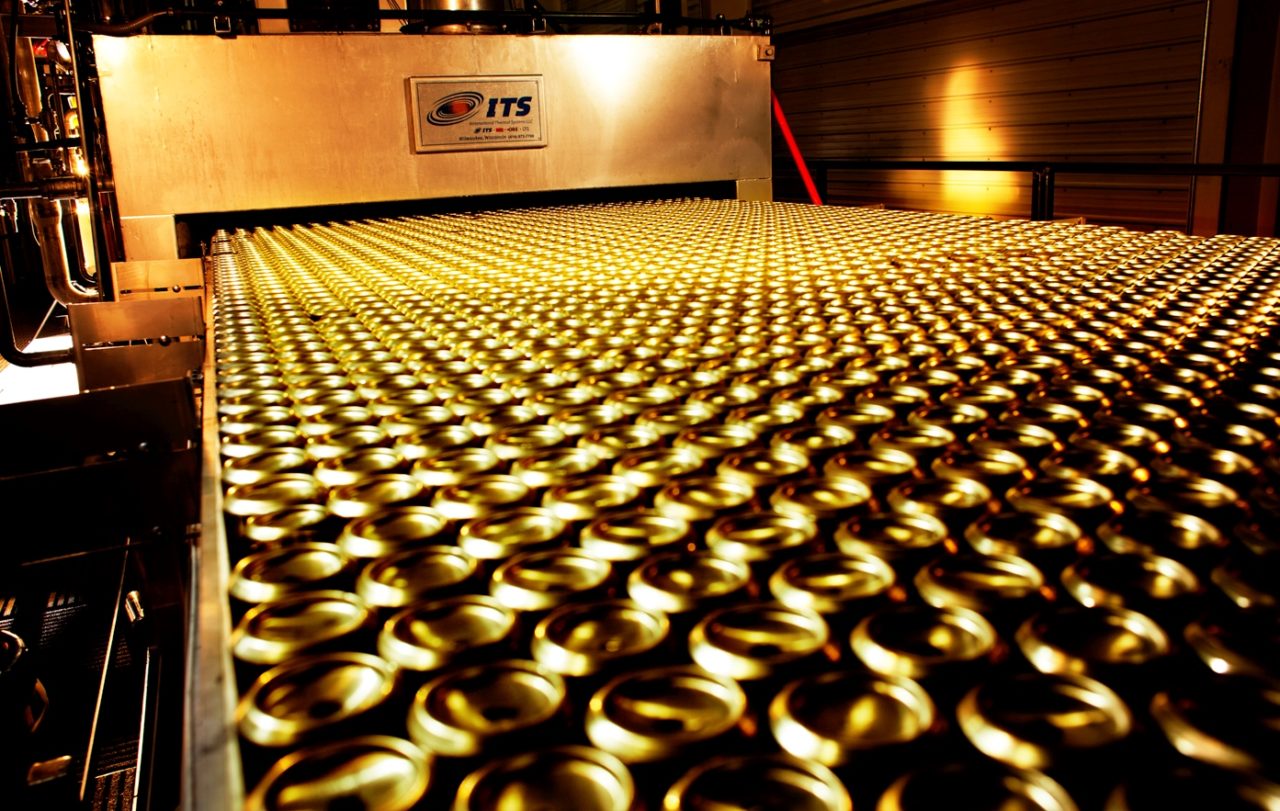

The Pin Oven is designed to cross link external inks, varnishes, and/or basecoat on the exterior of the cans so they can be handled during the next processes of production without damage to the external finish. ITS pin ovens are designed with patented airflow technology that delivers recirculated hot air to the cans and have been industry proven to provide the fastest and most uniform can heating available on the market.

Pin Oven

Overview

The Patented 7.10™ Pin Oven.

In 7 seconds at 10 passes, the patented 7.10™ Pin Oven thermally cross links the exterior coating on aluminum or steel beverage cans for base coat or decorating applications.

The air delivery system in the patented 7.10™ Pin Oven reduces the chain passes while maintaining the required time at temperature on the can. Less chain passes ultimately extend the pin chain life and reduce centrifugal forces on the cans.

Our patented air delivery system provides the shortest time to achieve peak metal temperature while eliminating can spoilage. This allows our pin ovens to work faster and more efficiently than any other on the market today and to do so in a smaller footprint.

Features

- Patented 7.10™ Pin Oven air delivery system provides the fastest uniform heat transfer efficiency resulting in the smallest equipment footprint in the industry.

- Production rates up to 2,400 Cans Per Minute (CPM).

- The patented 7.10™ Pin Oven design accommodates multiple pin lengths.

- Absence of air return wall allows direct access to the oven interior.

- Interior catwalk creates easy access for maintenance.

- Automatic chain cleaner, lubrication, and take up will extend chain life.

- Ambient air cooler system.

- Air knife systems to stabilize cans at the entrance and exit of the oven.

- Variable Frequency Drives (VFDs).

Specifications

- Heavy gauge Aluminium Steel

- High-density energy-saving insulation

- Panel and can type construction

- Sealed interior to prevent condensate leakage

- Access to the interior of the oven, fan, and burner chamber

Heat Sources

- LPG

- Natural Gas

- Fuel Oil

- Other Fuel Mixtures

Material Handling Options

- Air Knife Systems to stabilize cans at the entrance and exit of the oven

- Accommodates multiple pin lengths

Options

- 96 or 126 Tooth Sprocket Design

- 10 or 13 Degree

- Right and Left Hand

Temperature Ranges Up to 415°F (212°C)

Power Source Options

- Main Power Supplies 208 to 690 Volt AC, 50 and 60 HZ

- Control Voltage 24 Volt DC or 120/220 Volt AC

Industries

- Aerosol

- Food

- Beverage

- Pet Food

Downloads

Pin Oven from ITS

International Thermal Systems Overview

Contact the Metal Packaging Group

We are ready to assist with application recommendations and product proposals.