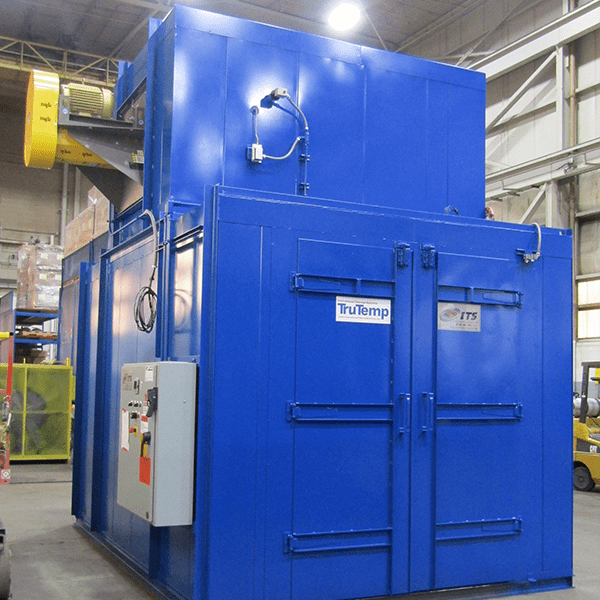

Out of Autoclave Composite Curing Oven for Advanced Composites

Companies in industrial industries including aerospace, automotive, and sporting goods, among others, depend on ITS’ Composite Curing Ovens to cure high strength, low weight carbon composite materials.

Our thermal airflow design experts design, build and install ovens renown for their temperature uniformity and state of the art technology for monitoring, controlling and managing the challenging composite curing process.