Step 4: Review and Approve: Operational Review and Washer General Assembly Drawing

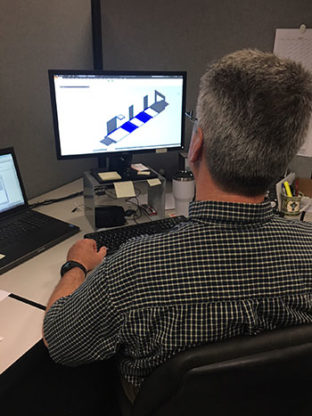

You are now on your way to a new industrial parts washer! You have chosen a manufacturer and are ready to get the project moving. After a contract is signed, the project moves to detailed engineering. At this time, the manufacturer may assign a project engineer to oversee the project. The project engineer may present an operational review to your entire team.

After the PO has been issued, the engineer will prepare a general assembly drawing of the industrial washer for your final review and approval. What is the key to success during this phase? Communication.

During the design/build phase of your machine, continued open communication with the sales team and the project engineer is recommended. Changes to your machine can be made during the design phase by communicating with the sales team and the project engineer. During the design phase the project engineer may contact you with any questions or issues that may have been overlooked during the initial purchasing process.

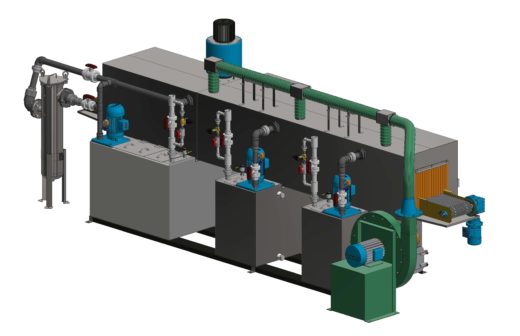

The operational review would be a precursor to the project engineer’s preparation of a General Assembly Drawing for your review and approval. This basic drawing will have the outside dimensions of the washer, the major components labeled, and should give you an idea of any work within your facility you need to have done within your facility for the washer to be installed. Once approved, final drawings will be created and the build of your machine can begin.

From a best practices perspective, here’s a list of items that you should expect during the operational review and general assembly drawing process:

- A realistic 3-D rendering of the washer

- Fixes for any speed bumps the engineer identifies regarding space limitations, power availability, or impact of requested upgrades on cost or deliverability timing

- A detailed discussion of installation issues and recommend fixes

Drawings are complete and have been approved. Now it is time to move to manufacturing.

We have created a guide to help navigate the manufacturing process of an Industrial Parts Washer. Download the guideand contact us with any questions.

ITS Washer Division

Shawn Fields – Sales Manager – East, shawn.fields@itsllcusa.com

Eric Zills – Sales Manager – West, eric.zills@itsllcusa.com

414.672.7700

To read the complete 6 step guide to Building an Industrial Parts Washer, download the article.